Direct Fired Heaters: Components in the Design

What is a direct fired heater? Also known as an industrial furnace, a fired heater is a direct-fired heat exchanger that uses the hot gases of combustion to increase the temperature of a feed flowing through coils of tubes aligned throughout the heater. [1]

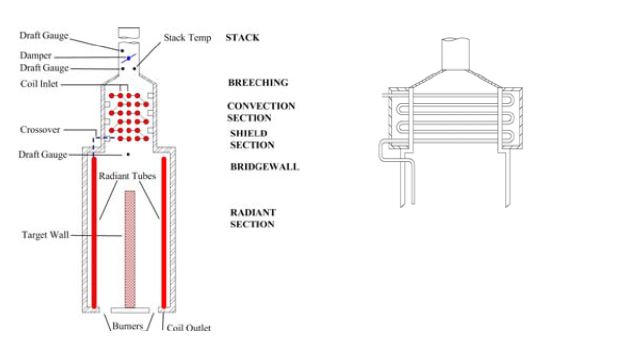

There are various furnace designs for different functions, but all share several common features and components to its design. They include the following: Radiant section, Convection section, Shield section and Stack and Breeching sections.

- Radiant section

The radiant tubes are located along the walls of the radiant section and receive radiant heat directly from the burners at the bottom or target wall in the middle. Most of the heat is gained in the radiant zone which is lined with refractory lining.

- Convection section

This section consists of the coil inlet, which is preheated by a feed charge. The convection section removes heat from the flue gas to preheat the contents of the tubes and significantly reduces the temperature of the flue gas exiting the stack.

- Shield section

This section contains rows of tubing which protects the tubes from direct heat.

- Stack and Breeching sections

Heat is transferred from the convection section to the stack by breeching.

Direct fired heaters are efficient, has a lower fuel consumption rate and lower operating costs as compared to indirect fired heaters. Due to it’s design, direct fired heaters are easy to transport and easy to maintain. However, certain safety precautions need to be taken such as ensuring there is sufficient ventilation in the room as certain levels of air is needed when operating. Other aspects include considering fuel type, combustion chemistry, heat transfer and release, combustion air supply and control and many more.

Direct-Fired Heaters: Their Design & Operation is a 3-day course held in Kuala Lumpur, Malaysia, from 22 – 24 October 2018. The course is crafted to allow engineers to better understand the many functions of direct fired heaters. On top of that, the trainer will also go in-depth into improving heater designs to increase efficiency while meeting emission guidelines. For more information, please visit us at http://www.opuskinetic.com/training or contact us at info@opuskinetic.com

Opus Kinetic believes that people are why organisations are successful, and giving people the knowledge to perform well at their job is integral for success. We pride ourselves as the premier provider of knowledge, offering acclaimed in-house training, leadership training courses, oil and gas training courses, courses that target health safety and environment, etc. Our training courses are well researched and updated with the latest industry trends. For more information on our professional training programs, you can visit us at http://www.opuskinetic.com/training.

[1] https://www.researchgate.net/profile/Bedica_Bedica/publication/257728119_FIRE_HEATER_ENGINEERING_ECONOMICS_DESIGN/links/00b49525c31c4588fe000000/FIRE-HEATER-ENGINEERING-ECONOMICS-DESIGN.pdf