3 Lethal Process Safety Incidents

Major industrial process safety incidents highlight the need for good process safety management (PSM) systems in place within the oil and gas and petrochemical industry. Industrial incidents caused by failures of PSM systems are deadly and costly. For example, a fire and explosion accident at a PEMEX LPG terminal in Mexico City, left 600 dead and 7,000 injured. These incidents serve as an important reminder for companies to constantly review and improve safety protocols and equipment to be prepared in the event of dire emergency situations.

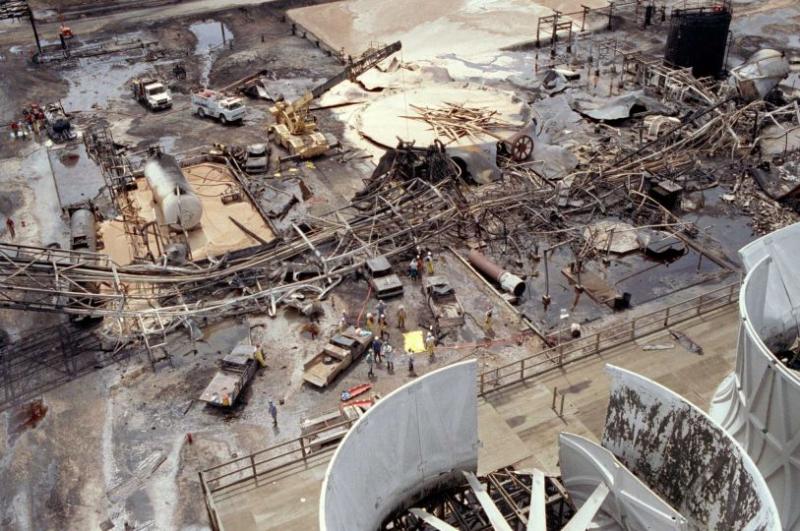

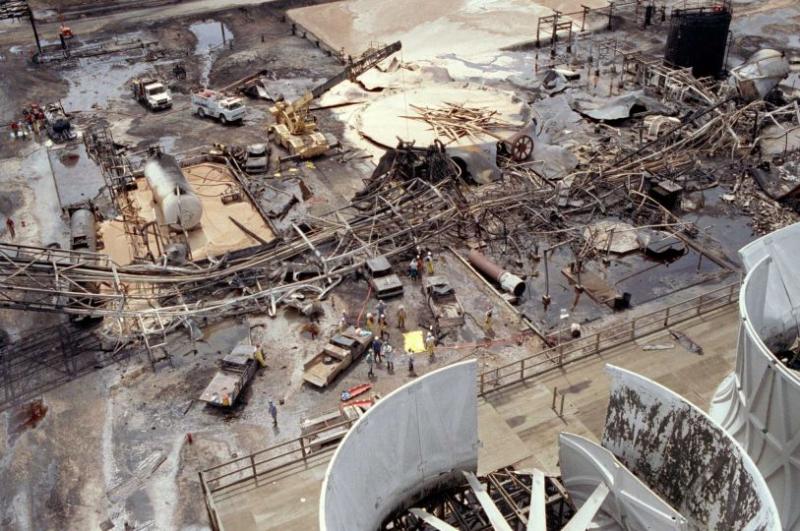

ARCO wastewater tank explosion

A wastewater tank exploded during the restart of a compressor in 1990. The failure to detect the increase in oxygen in the atmosphere led to formation of a flammable atmosphere in the tank. During the restart of the compressor, the tank ignited and killed 17 people. Damages were estimated to be $100 million.

Terra Industries plant explosion

The explosion was caused due to the lapses in the vessel shutdown operating procedures. Ammonium nitrate solution was found in several vessels, and combined with other conditions such as the strong acidic conditions in the neutralizer, led to the explosion which killed 4 people and 18 injured.

The explosion was caused due to the lapses in the vessel shutdown operating procedures. Ammonium nitrate solution was found in several vessels, and combined with other conditions such as the strong acidic conditions in the neutralizer, led to the explosion which killed 4 people and 18 injured.

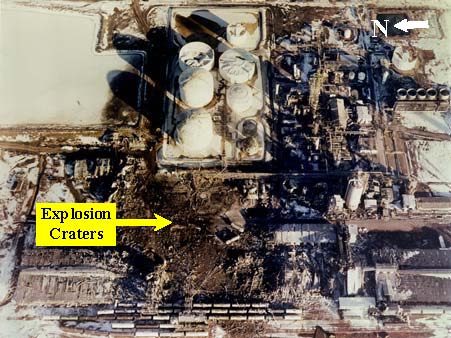

Formosa Plastics plant fire and explosion

An explosion and fire at the Formosa Plastics plant was caused by the lack of operating procedures and protocols in place. Employees were also unprepared for major accidents at the facility. The explosion killed 5 workers and seriously injured 2 of them. The failure to follow operating procedures and poor communication ultimately led to the explosion, further highlighting the importance of proper emergency response planning and good PSM systems.

Reference

https://www.aiche.org/sites/default/files/cep/20150323.pdf

Excellence in Plants Process Safety is a 3-day course held from 19 – 21 September (Singapore) and 24 – 26 September (Kuala Lumpur), to allow participants to learn how to develop and implement best practices in process safety management in process plants. Participants will learn to recognise process safety risks and be able to apply key techniques for analysing them. For more information, please visit us at http://www.opuskinetic.com/training or contact us at info@opuskinetic.com.

Opus Kinetic believes that people are why organisations are successful, and giving people the knowledge to perform well at their job is integral for success. We pride ourselves as the premier provider of knowledge, offering acclaimed in-house trainings, and many others professional training courses spanning from various industries. Our training courses are well researched and updated with the latest industry trends. For more information on our professional training programs, visit us at http://www.opuskinetic.com/training.